DE | EN

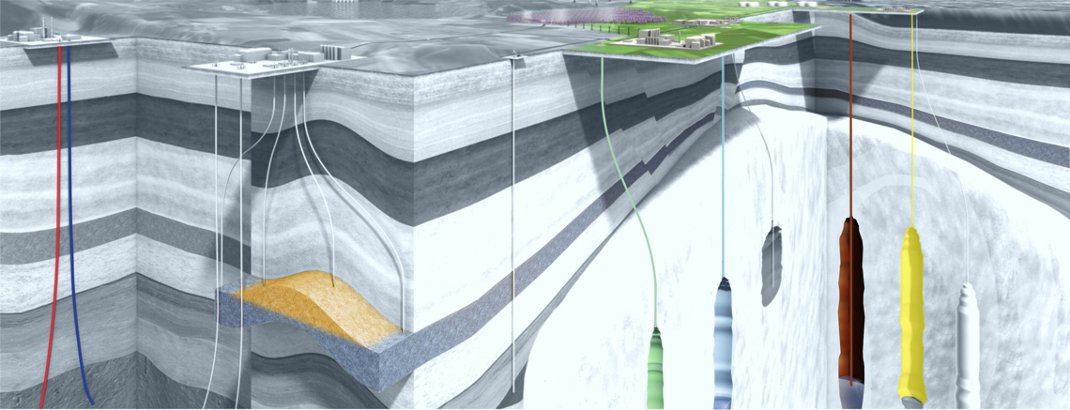

INNOVATIVE ENERGY STORAGE.

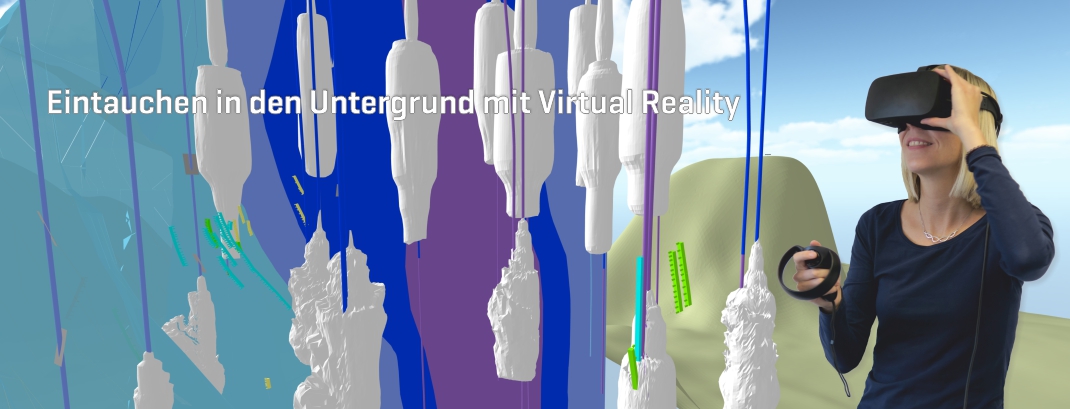

DEEP.KBB ist spezialisiert auf ingenieur- und geowissenschaftliche Dienstleistungen für die verschiedensten Untertageprojekte. Die Planung, der Bau und der Betrieb von untertägigen Energiespeichern sowie von Anlagen zur Sole- und Salzgewinnung bilden unsere Kernkompetenz.

Unser Know-how ist in jahrzehntelanger Erfahrung gewachsen. Ob es um Tiefbohr- oder Komplettierungstechnik, Dichtheitstests, Geologie, Gebirgsmechanik, Reservoir Engineering oder Bohrungs- und Speicherintegrität geht: Sprechen Sie uns an!